In a marketplace inundated with products vying for attention, packaging does more than protect it makes a statement. Whether you’re launching a snack pouch, a premium cosmetic tube, or a shrink sleeve for a beverage, the visual finish and surface performance matter. This is where selecting a trusted UV coatings partner becomes essential. A top-tier UV Coatings Manufacturer for Packaging delivers not just aesthetic lift, but durability, functionality and brand value. Innokan, with its deep expertise in specialty coatings and sustainable practices, exemplifies how the right supplier plays a strategic role in packaging success.

Why UV Coatings Matter in Packaging

UV-cured coatings are increasingly preferred in premium packaging segments. Their benefits include:

- Instant curing and high durability: Once exposed to UV light, the coating rapidly polymerises into a tough, abrasion-resistant film.

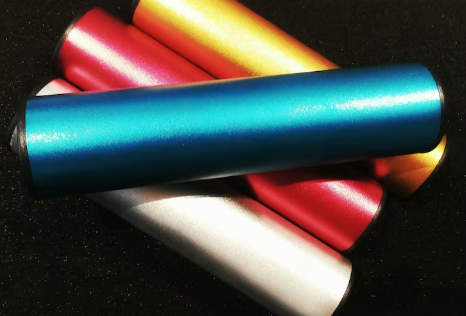

- High-gloss, matte, textured or tactile finishes: This ability to customise surface finish improves shelf appeal and brand differentiation.

- Minimal VOC emissions and fast production turnaround: Many UV systems are solvent-free and dry instantly, improving production efficiency.

- Enhanced protection: Good UV coatings offer scratch resistance, chemical resistance and protect printed graphics during transit and handling.

Given these advantages, brands that prioritise sustainable, high-impact packaging benefit enormously by working with a specialised supplier.

What to Look for in a Packaging Coating Partner

When seeking your UV coatings supplier, evaluate across multiple dimensions:

- Technological Capabilities & Finish Variety

Look for a manufacturer who offers gloss, matte, soft-touch, texture and speciality effects. Innokan showcases a robust suite of UV coatings, as well as other coating technologies like release and heat-seal systems. - Substrate Compatibility & Production Line Support

Your coatings must perform across films, foils, paper and laminates. Ensure that the supplier has experience with your substrate and supports high-speed lines without defects. - Sustainability & Regulatory Compliance

With increasing regulatory scrutiny and brand-level ESG commitments, your coating partner should provide VOC-free or water-based alternatives, food-contact certifications (if applicable) and documented environmental credentials. Innokan emphasises sustainable manufacturing and green chemistry. - Quality Assurance & Reproducibility

Consistent coat-weight, absence of visual defects (orange peel, pinholes, lift off), strong adhesion and uniformity across runs are critical. Strong suppliers will have rigorous QC routines and published performance data. - Customisation & Service Level

Whether you need a textured finish for a luxury brand or a high-barrier coating for active packaging, the supplier must be willing to tailor formulations, support trials and scale quickly. Innokan’s speciality coatings portfolio emphasises flexibility and customer-specific solutions. - Geographic Reach & Logistical Support

Timely supply, local service, colour-matching, reverse logistics for rejects all reduce your risk. Having a supplier positioned close to your production base is an added advantage.

The Impact of Working with Innokan

Choosing Innokan as your UV coatings partner brings several strategic benefits:

- High-Performance End-Product: With advanced formulations for UV coatings, release coatings and heat-seal coatings, you’re positioned for premium end-product quality.

- Brand Enhancement: Whether it’s razor-sharp graphics, tactile finishes or luxury packaging, the coatings help your brand stand out on shelf.

- Operational Efficiency: Fast drying, minimal downtime and fewer rejects translate into reduced overall cost and improved throughput.

- Sustainability Credentials: Leveraging formulations with lower environmental impact aligns with brand and regulatory demands again reinforcing market positioning.

- Support for Growth: As your packaging volumes scale or your design needs evolve, Innokan’s flexible infrastructure supports new effects, higher-speed lines and more complex jobs.

Real-World Examples & Use-Cases

Consider a premium cosmetics brand that wanted a “velvet-touch” finish on its carton. With a standard coating supplier, the production yield dropped, and defects increased. By switching to a specialised UV coating partner, they achieved the tactile finish, stable adhesion, improved shelf feel, and lower defect rates directly contributing to brand perception and reduced rework.

Similarly, a snack food brand deploying high-speed film lines (500 m/min) needed coatings that cure instantly and survive high-speed processing and high VOC regulations. The right UV coatings partner supported smooth line runs, minimal downtime and durable finish improving productivity and appearance.

Making the Decision: Key Questions to Ask

Before finalising your coatings partner, ask:

- What are your coatings’ cure speeds, adhesion ratings, scratch resistance metrics?

- Can you supply sample reports and run history on my substrate/line type?

- What is your colour-matching process, and how do you handle shade control?

- What levels of technical support, troubleshooting and field service do you provide?

- What lead-times do you guarantee for standard and custom coatings?

- What sustainability credentials and certifications (food contact, recyclability) do you hold?

Final Thoughts: Packaging That Performs & Persuades

In packaging, the finish isn’t just decorative it conveys brand trust, durability and quality to consumers. Working with the right coatings partner transforms your packaging from functional to persuasive, from commodity to premium. As you evaluate your options, keep in mind that cost-per-metre is only part of the equation yield impact, line-speed reliability, scrap reduction and brand appeal all factor in.

For brands looking to make packaging shine and perform today and tomorrow, partnering with a robust specialist coating supplier like Innokan is a strategic choice. With the right support, your packaging can elevate visually, perform consistently and deliver long-term value.

FAQs

What are the main benefits of UV coatings for packaging?

UV coatings provide rapid curing, high gloss or texture finishes, enhanced abrasion resistance and improved visual appeal making packaging stand out while maintaining durability.

How do I choose between UV coatings and conventional varnishes?

Choose UV coatings when speed, durability, scratch resistance and premium appearance matter. Conventional varnishes may be less expensive but may not perform as well on high-speed lines or premium segments.

Can UV coatings be applied on any substrate?

Yes as long as the substrate (film, foil, paper, laminate) is properly prepared. A good coatings partner evaluates your substrate, machine speed, ink type and finish goals to tailor the coating.

How does sustainability factor into choosing packaging coatings?

Modern coating suppliers offer VOC-free, water-based or low-emission UV systems. Brands increasingly demand recyclability and reduced environmental impact so sustainability credentials matter.

How much does a premium UV coating add to my packaging cost?

Cost varies widely depending on coat weight, finish type, substrate and run length. Rather than just comparing per-metre cost, focus on total value reduced scrap, faster line-speeds, fewer defects and enhanced consumer perception.